M1 Garand

From Wikipedia, the free encyclopedia

The M1 Garand (officially designated as United States Rifle, Caliber .30, M1 and later

simply Rifle, Caliber .30, M1, and also abbreviated as US Rifle, Cal. .30, M1), was the

first semi-automatic rifle to be generally issued to the infantry of any nation.

Called "the greatest battle implement ever devised" by General George S. Patton,

the Garand officially replaced the bolt-action M1903 Springfield as the standard

service rifle of the United States Armed Forces in 1936 and was subsequently replaced

by the selective fire M14 in 1957. However, the M1 continued to be used in large

numbers until 1963 and to a lesser degree until 1966.

The M1 "is an air-cooled, gas-operated, clip-fed, and semiautomatic shoulder weapon.

This means that the air cools the barrel; that the power to cock the rifle and chamber

the succeeding round comes from the expanding gas of the round fired previously; that

it is loaded by inserting a metal clip (containing a maximum of eight rounds) into

the receiver; and that the rifle fires one round each time the trigger is pulled ".

After the eight rounds have been shot the clip automatically ejects causing a

"ping" noise to occur.

The M1 was used extensively by U.S. forces in World War II, the Korean War, and, to

a limited extent, the Vietnam War. Most M1 rifles were issued to Army and Marine

troops, though many thousands were also lent or provided as foreign aid to America's

allies. The Garand is still used by drill teams and military honor guards. It is also

widely sought by the civilian population as a hunting rifle, target rifle, and

military collectible. The name "Garand" is pronounced /ɡəˈrænd/ or /ˈɡærənd/.

According to experts and people who knew John Garand, the weapon's designer, the

latter version is preferred. It is available for American civilian ownership

through the Civilian Marksmanship Program.

History

Though the U.S. Army became interested in self-loading rifles with the Bang and

Murphy-Manning of 1911, and there were pre-production models in 1916, the M1's origin

properly dates to 1919, when armies around the world were realizing standard rifle

cartridges were more powerful than necessary for typical engagement ranges, leading to

heavier rifles than really required. The Army trials in the 1920s had a .256 inch

minimum caliber requirement, compared to the .30-06 then standard.

Development

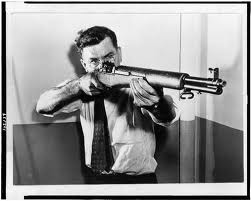

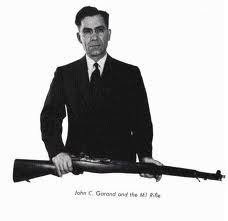

Canadian-born Garand went to work at the United States Army's Springfield Armory and

began working on a .30 caliber primer-operated breech. In the summer of 1924,

twenty-four rifles, identified as "M1922", were built at Springfield. At Fort Benning

during the summer of 1925, they were tested against models by Berthier, Hatcher-Bang,

Thompson, and Pedersen, the latter two being delayed blowback types. This led to a

further trial of an improved "M1924" Garand against the Thompson, ultimately producing

an inconclusive report. As a result, the Ordnance Board ordered a .30-'06 Garand

variant.

In March 1927, the Cavalry Board reported trials between the Thompson, Garand,

and '03 Springfield had not led to a clear winner. This led to a gas-operated

.276 model (patented by Garand on 12 April 1930).

During the spring of 1928, both Infantry and Cavalry Boards ran trials with the .276

Pedersen T1 rifle, calling it "highly promising" (despite its use of waxed

ammunition, shared by the Thompson). On 13 August 1928, a Semiautomatic Rifle

Board carried out joint Army, Navy, and Marine Corps trials between the .30 Thompson,

both cavalry and infantry versions of the T1 Pedersen, "M1924" Garand, and .256 Bang,

and on 21 September, the Board reported no clear winner. The .30 Garand, however, was

dropped in favor of the .276. Further tests by the SRB in July 1929, which included

rifle designs by Browning, Colt-Browning, Garand, Holek, Pedersen, Rheinmetall,

Thompson, and an incomplete one by White, led to a recommendation that work on

the (dropped) .30 gas-operated Garand be resumed, and a T1E1 was ordered 14 November

1929. Twenty gas-operated .276 T3E2s Garands were made and competed with T1 Pedersen

rifles in Spring 1931. The .276 Garand was the clear winner of these trials. The .30

caliber Garand was also tested, in the form of a single T1E1, but was withdrawn with a

cracked bolt on 9 October 1931. A 4 January 1932 meeting recommended adoption of the

.276 caliber and production of approximately 125 T3E2s. Meanwhile, Garand redesigned

his bolt and his improved T1E2 rifle was retested. The day after the successful

conclusion of this test, Army Chief of Staff General Douglas MacArthur personally

disapproved any caliber change, in part because there were extensive existing stocks

of .30 M1 ball ammunition. On 25 February 1932, Adjutant General John B. Shuman,

speaking for the Secretary of War, ordered work on the rifles and ammunition in .276

caliber cease immediately and completely and all resources be directed toward

identification and correction of deficiencies in the Garand .30 caliber.

On 3 August 1933, the T1E2 became the Semi-Automatic Rifle, Caliber 30, M1. In May

1934, 75 M1s went to field trials; 50 were to infantry, 25 to cavalry units. Numerous

problems were reported, forcing the rifle to be modified, yet again, before it could

be recommended for service and cleared for procurement on 7 November 1935, then

standardized 9 January 1936. The first production model was successfully

proof-fired, function-fired, and fired for accuracy on July 21, 1937.

Production difficulties delayed deliveries to the Army until September 1937.

Machine production began at Springfield Armory that month at a rate of ten rifles per

day, and reached an output of 100 per day within two years. Despite going into

production status, design issues were not at an end. The barrel, gas cylinder, and

front sight assembly were redesigned and entered production in early 1940. Existing

"gas-trap" rifles were recalled and retrofitted, mirroring problems with the earlier

M1903 Springfield rifle that also had to be recalled and reworked approximately three

years into production and foreshadowing rework of the M16 rifle at a similar point in

its development. Production of the Garand increased in 1940 despite these

difficulties, reaching 600 a day by 10 January 1941, and the Army was fully equipped

by the end of 1941.

Service Use

Following the outbreak of World War II in Europe, Winchester was awarded an

"educational" production contract for 65,000 rifles, with deliveries beginning in

1943. The British Army looked at the M1 as a possible replacement for its

bolt-action Lee-Enfield No.1 Mk III, but it was rejected when rigorous testing

suggested that it was an unreliable weapon in muddy conditions.

The M1's semiautomatic operation gave United States forces a significant advantage in

firepower and shot-to-shot recovery time over individual enemy infantrymen in battle

(German, Italian, and Japanese soldiers were usually armed with bolt-action rifles).

General George S. Patton called it "the greatest implement of battle ever devised."

The impact of faster-firing infantry small arms in general soon stimulated both

Allied and Axis forces to greatly augment issue of semi- and fully automatic

firearms then in production, as well as to develop new types of infantry firearms.

Much of the M1 inventory in the

post-World War II period underwent arsenal repair or

rebuilding. While U.S. forces were still engaged in the Korean War, the Department of

Defense determined a need for additional production of the Garand, and two new

contracts were awarded. During 1953-56, M1s wre produced by International Harvester

and Harrington & Richardson. A final, very small lot of M1s was produced by

Springfield Armory in early 1957, using finished components already on hand. Beretta

also produced Garands using Winchester tooling. U.S. Army Infantryman in 1942 with

M1, Fort Knox, KY. The M1 proved an excellent rifle throughout its service in World

War II and the Korean War. Surplus M1 rifles also armed many nations allied to the

United States postwar, including West Germany, Italy and Japan. Some Garands were

still being used in the Vietnam War in 1963; despite the M14's official adoption in

1957, it was not until 1965 the changeover from the M1 Garand was completed in the

active-duty component of the Army (with the exception of the sniper variants, which

were introduced in World War II and saw action in Korea and Vietnam). In other

components of the armed forces, such as the Army Reserve, Army National Guard and

the Navy, Garands continued to serve into the 1970s or longer.

Some military drill

teams still use the M1, including the U.S. Marine Corps Silent Drill Team, the

Norwegian Royal Guards Drill Team, the United States Air Force Academy Cadet Honor

Guard, almost all Reserve Officer Training Corps (ROTC) and some Junior Reserve

Officer Training Corps (JROTC) teams of all branches of the U.S. military. The

Greek Army Evzones (presidential) Guard still uses M1s, and it was used as a

training rifle in the Greek army even in the late 1990s.

Design Details

The M1 rifle is a gas-operated, semi-automatic, clip-fed rifle. By modern

standards, the M1's feeding system is archaic, relying on clips to feed ammunition,

and is the principal source of criticism of the rifle. Officials in Army Ordnance

circles demanded a fixed, non-protruding magazine for the new service rifle. At the

time, it was believed that a detachable magazine on a general-issue service rifle

would be easily lost by U.S. soldiers (a criticism made of British soldiers and the

Lee-Enfield 50 years previously), would render the weapon too susceptible to clogging

from dirt and debris (a belief that proved unfounded with the adoption of the M1

Carbine), and that a protruding magazine would complicate existing manual-of-arms

drills. As a result, inventor John Garand developed an "en bloc" clip system that

allowed ammunition to be inserted from above, clip included, into the fixed magazine.

While this design provided the requisite flush-mount magazine, the clip system

increased the rifle's weight and complexity, and made only single loading ammunition

possible without a clip.

Garand's rifle was originally chambered for the .276 Pedersen cartridge, charged

by means of 10-round clips. Later, it was chambered for the then-standard .30-06

Springfield. With this new cartridge, the M1 had a maximum effective range of 440

yards (400 m),

with the capability of inflicting a casualty with armor-piercing

ammunition well beyond 875 yards (800 m). Because of the larger diameter of the

.30-06 cartridge, the modified clip held only eight rounds.

Two of Garand's patents, showing the original gas trap design and revised gas port

system. Garand's original design for the M1 used a complicated gas system involving a

special muzzle extension gas trap, later dropped in favor of a simpler drilled gas

port. Because most of the older rifles were retrofitted, pre-1939 gas-trap M1s are

very rare today and are prized collector's items. In both systems, expanding gases

from a fired cartridge are diverted into the gas cylinder. Here, the gases met a

long-stroke piston attached to the operating rod. The operating rod was therefore

pushed rearward by the force of this high-pressure gas. Then, the operating rod

engaged a rotating bolt inside the receiver. The bolt was attached to the receiver

via two locking lugs, which rotated, unlocked, and initiated the ejection of the spent

cartridge and the reloading cycle when the rifle was discharged. The operating rod

(and subsequently the bolt) then returned to its original position.

Features

The weight of the M1 varies between 9.5 pounds (4.31 kg) and 10.2 pounds (4.63 kg)

unloaded (depending on sling type and stock wood density)—a considerable increase over

the previous M1903 Springfield. The length was 43.6 inches (1,107 mm). The rifle is

fed by an "en bloc" clip which holds eight rounds of .30-06 Springfield ammunition.

When the last cartridge is fired, the rifle ejects the clip and locks the bolt open.

Clips can also be manually ejected at any time. The "en-bloc" clip is manually

ejected by pulling the operating rod all the way to the rear, and then depressing

the clip latch button. Much criticized in modern times, the en-bloc clip was

innovative for its era.

The concept of a disposable box magazine had not been

embraced, and en-bloc clips were cheap and reliable. Contemporary rifles with the

ability to easily top off a magazine included the Johnson M1941, the obsolete

Krag-Jørgensen and the Lee-Enfield No1 and No4. The rifle's ability to rapidly

fire powerful .30-06 rifle ammunition also proved to be of considerable advantage in

combat. In China, Japanese banzai charges had previously met with frequent success

against poorly trained Chinese soldiers armed with bolt-action rifles. Armed with the

M1, U.S. infantrymen were able to sustain a much higher rate of fire than their

Chinese counterparts. In the short-range jungle fighting, where opposing forces

sometimes met each other in column formation on a narrow path, the penetration of

the powerful .30-06 M2 cartridge enabled a single U.S. infantryman to kill up to three

Japanese soldiers with a single round. The Garand's fire rate in the hands of a

trained soldier, averaged out to 40–50 accurate shots per minute at a range of 300

yards, making it the single fastest-firing service rifle of any nation by a wide

margin. Ejection of an empty clip created a distinctive metallic "pinging" sound.

In World War II, reports arose in which German and Japanese infantry were making use

of this noise in combat to alert them to an empty M1 rifle in order to 'get the drop'

on their American enemies. The information was taken seriously enough that U.S. Army's

Aberdeen Proving Ground began experiments with clips made of various plastics in order

to soften the sound,

though no improved clips were ever adopted. According to

former German soldiers, the sound was inaudible during engagements and not particularly

useful when heard, as other squad members might have been nearby ready to fire.

The M1 Garand was one of the first self-loading rifles to use stainless steel for

its gas tube, in an effort to prevent corrosion. As the stainless metal could not

be parkerized, the gas tubes were given a stove-blackening that frequently wore off

in use. Unless the gas tube could be quickly repainted, the resultant gleaming muzzle

could make the M1 Garand and its user more visible to the enemy in combat. The M1

Garand was designed for simple assembly and disassembly to facilitate field

maintenance. It can be field stripped (broken down) without tools in just a few

seconds.

Operation

The Garand is loaded with a full clip of eight rounds. Once all eight rounds are

expended, the bolt will be automatically locked back and the clip ejected (with a

distinct metallic ping), readying the rifle for the insertion of a fresh clip of

ammunition. Compared to contemporary detachable box magazines, the M1's "en bloc"

clip is light, simple, and only has to be oriented with the rounds pointing forward

prior to charging the rifle (the clips have no top or bottom).

Once the clip is inserted, the bolt snaps forward on its own as soon as thumb pressure

is released from the top round of the clip, chambering a round and leaving it ready to

fire. The right hand should be placed in front of the operating rod handle in

order to prevent the bolt from closing on operator's thumb (resulting in "Garand thumb"

or "M1 thumb") and after the clip has been pressed into position in the magazine, the

operating rod handle should be released, allowing the bolt to snap forward under

pressure from the operating rod spring. The operating rod handle may be smacked with the

palm to ensure the bolt is closed.

The M1's safety catch is located at the front of the trigger guard. It is engaged when

it is pressed rearward into the trigger guard, and disengaged when it is pushed forward

and is protruding outside of the trigger guard. Contrary to widespread

misconception, partially expended or full clips can be easily ejected from the rifle

by means of the clip latch button. It is also possible to load single cartridges

into a partially loaded clip while the clip is still in the magazine, but this

requires both hands and a bit of practice. In reality, this procedure was rarely

performed in combat, as the danger of loading dirt along with the cartridges

increased the chances of malfunction. Instead, it was much easier and quicker to

simply manually eject the clip, and insert a fresh one, which is how the rifle

was originally designed to be operated. Later, special clips holding

two or five rounds became available on the civilian market, as well as a

single-loading device which stays in the rifle when the bolt locks back.

In battle, the manual of arms called for the rifle to be fired until empty, and then

recharged quickly. Due to the well-developed logistical system of the U.S. military at

the time, this wastage of ammunition was generally not critical, though this could

change in the case of units that came under intense fire or were flanked or surrounded

by enemy forces. The Garand's en-bloc clip system proved particularly cumbersome

when using the rifle to launch grenades, requiring removal of an often partially

loaded clip of ball ammunition and replacement with a full clip of blank cartridges.

It is recommended that very slow burning powders and heavy bullets not be used in the

Garand. This is an issue especially important to handloaders, as the pressure curve

of slower propellants can put too much pressure on the gas piston, bend the operating

rod, and adversely affect the Garand's accuracy. The Garand is best used with bullets

of about 150 grains weight, as in "Ball, Caliber 30, M2" ammunition. However, there

are several adjustable gas cylinder plugs available that vent excess gas out of the

gas cylinder, reducing the pressure on the operating rod.

Accessories

Both official and aftermarket accessories were plentiful for the Garand rifle. Several

different styles of bayonets fit the rifle: the M1905 and M1942, both with 16-inch

(406 mm) blades; the Model 1905E1 with shortened 10-inch (254 mm) blade; the M1 with

10-inch (254 mm) blade; and the M5 bayonet with 6.75-inch (152 mm) blade.

Also available was the M7 grenade launcher that fitted onto the end of the barrel. It

was sighted using the M15 sight, which fit just forward of the trigger.

A cleaning tool, oiler and greasepots could be stored in two cylindrical compartments

in the buttstock for use in the field. Because of the limitations of the Garand's

clip-loading magazine, the rifle proved less than ideal for use in launching 22 mm

rifle grenades, and the M1903 Springfield was retained for use in that role long after

grenade launchers for the Garand became available.

The M1907 two-piece leather rifle sling was the most common type of sling used with

the weapon through World War II. In 1943 a khaki canvas sling was introduced that

gradually became more common. Another accessory was the winter trigger, said to

have been developed during the Korean War. It consisted of a small mechanism installed

on the trigger guard, allowing the soldier to remotely pull the trigger by depressing

a lever just behind the guard. This enabled the shooter to fire his weapon while

using winter gloves, which could get "stuck" on the trigger guard or not allow for

proper movement of the finger.